SMART

SUPPLY CHAIN

SOLUTIONS

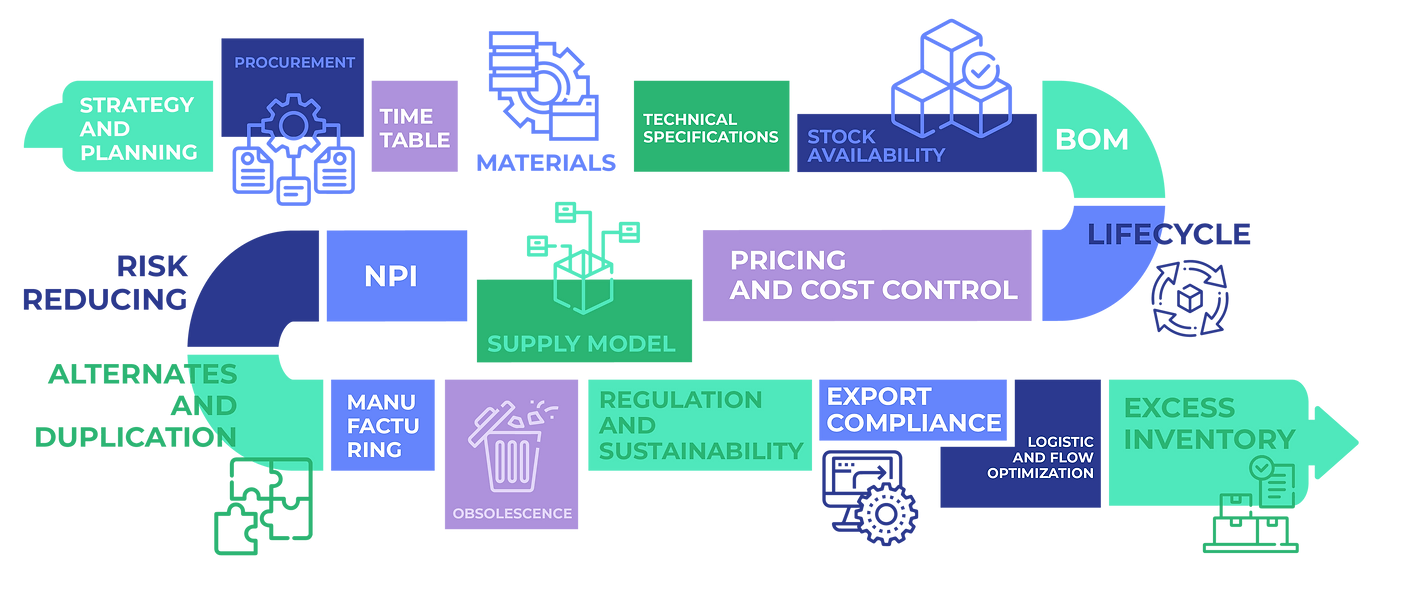

We’ve built novel pillars required to deliver supply durability for the electronics value chain. Our Design-to-market solutions use AI and technological operations for planning, procurement, manufacturing, flexibility, and logistics–assuring a steady supply flux, helping you reach a wider customer base, and reducing the overall operational costs.

STRATEGY and innovation for the electronic supply chain based on understanding the risks and challenges, from global shortage to complete business optimization.

PROCUREMENT from A – to Z. With solutions including planning, stock, lifecycle, costs control, materials, technical specifications, and logistics, BOM, alternates and duplication, obsolescence, NPI, regulation and sustainability.

FLEXIBILITY in finding alternative solutions to NCNR policy (non-cancellable / non-refundable).

SUPPLY MODEL that delivers results. The so far popular just-in-time supply chain model might be too slow in responding to sudden shocks. Let’s find the right model for you!

MANAGEMENT from Design to Market, taking full control and responsibility for system and services.

SYNERGIC SYSTEM with greater intelligence and increased collaboration across design, engineering, sourcing, and sales.

MANUFACTURING that Meets Demand with no minimum order requirements.

SUSTAINABILITY and compliance with environmental quality regulations of electronics, and the control of safe manufacturing in an ethical and sustainable manner.

LOGISTIC that deliver a full range of operation management.

Synergic

system,

why?

We believe that today’s electronic ecosystem provides challenges that requires greater intelligence and increased collaboration across design, engineering, sourcing, and sales. Mainly, when every part of the supply chain has become commercialized, and companies continue to push more complex product variants to remain competitive. Our supply chain solutions also apply relationships with partners, which may include suppliers, intermediaries, third-party service providers, and customers. Accordingly, we integrate supply and demand management within and between companies.

Manufacturing that

Meets Demand,

so?

- A factory network that expands your options and helps you bring products to market faster.

- Scalable production with no minimum order requirements. Scale up or down as you need.

- AI-enabled factory matching to improve efficiency and quality while keeping costs in check.

- Ai and machine learning in electronic components production

Flexibility,

how?

- Strategy planning based on real-time cost data and variable costs

- Product Change Notices Monitoring and fast transition to other solutions

- Alternative solutions to NCNR policy (non-cancellable / non-refundable)

- A Material Requirement Planning (MRP) strategy from order to stock

- Supply model adjustment and alternatives by value engineering

- Management of bottlenecks

Full Logistic

management,

yes!

Full range of operational management for your supply chain: Customized solutions covering

Complete traceability using advanced technologies, from products, Shipping, and transportation.